Plastic Gear Molding

Plastic Gear Molding

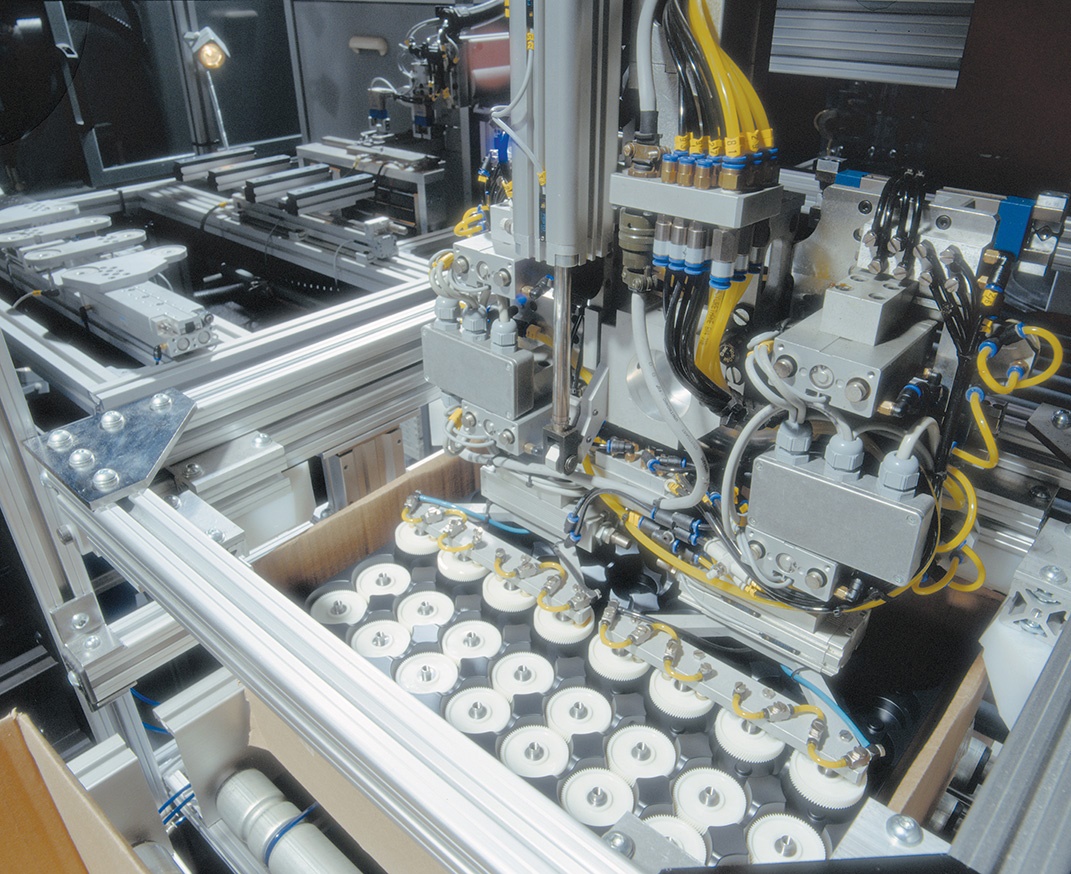

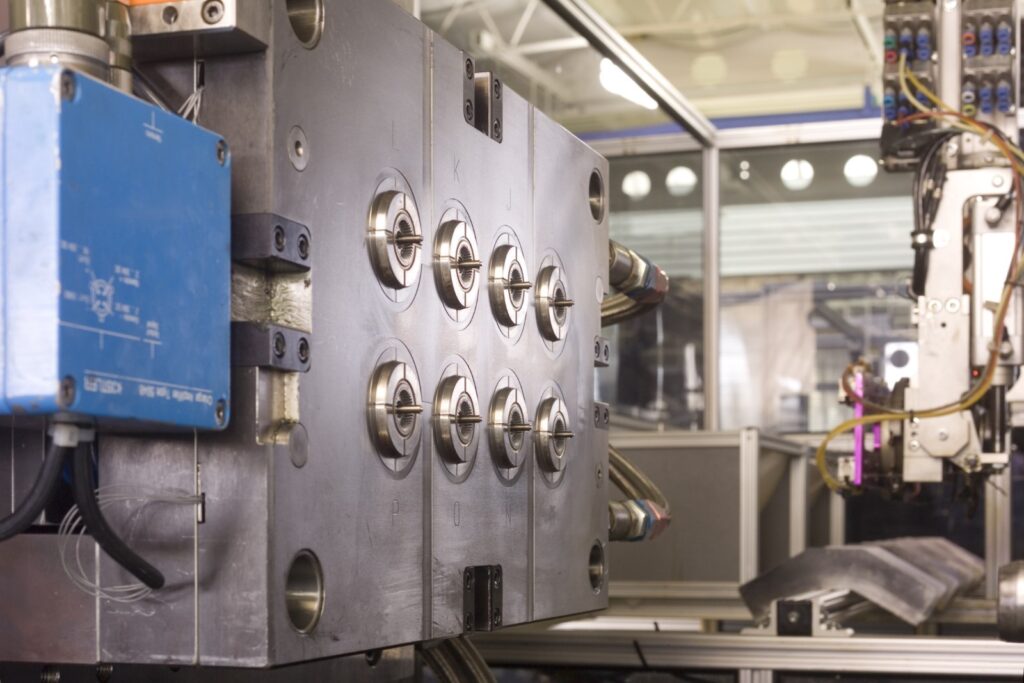

Creating the best gear design is only the start of production: the next step is molding the gear itself. Prototype molding and quality validation are essential before constructing production molds, and at Winzeler Gear, we utilize gear molding as an optimization step allowing us to test alternate material, thinner wall sections, and other cost-saving opportunities for production.

The best-molded gears start from the best designs, and Winzeler Gear understands the importance of optimizing component gears before production. Prototype gear molding is the best way to end up with the best possible gears for your application.

Contact us today to learn more about our gear molding services.

SCIENTIFIC MOLDING

The proper execution of scientific molding is critical to maintaining consistent quality for a gear with high tolerances and demanding structural stability requirements. Winzeler Gear will always ensure all your molded gears perform consistently with the help of our data-driven scientific molding process.

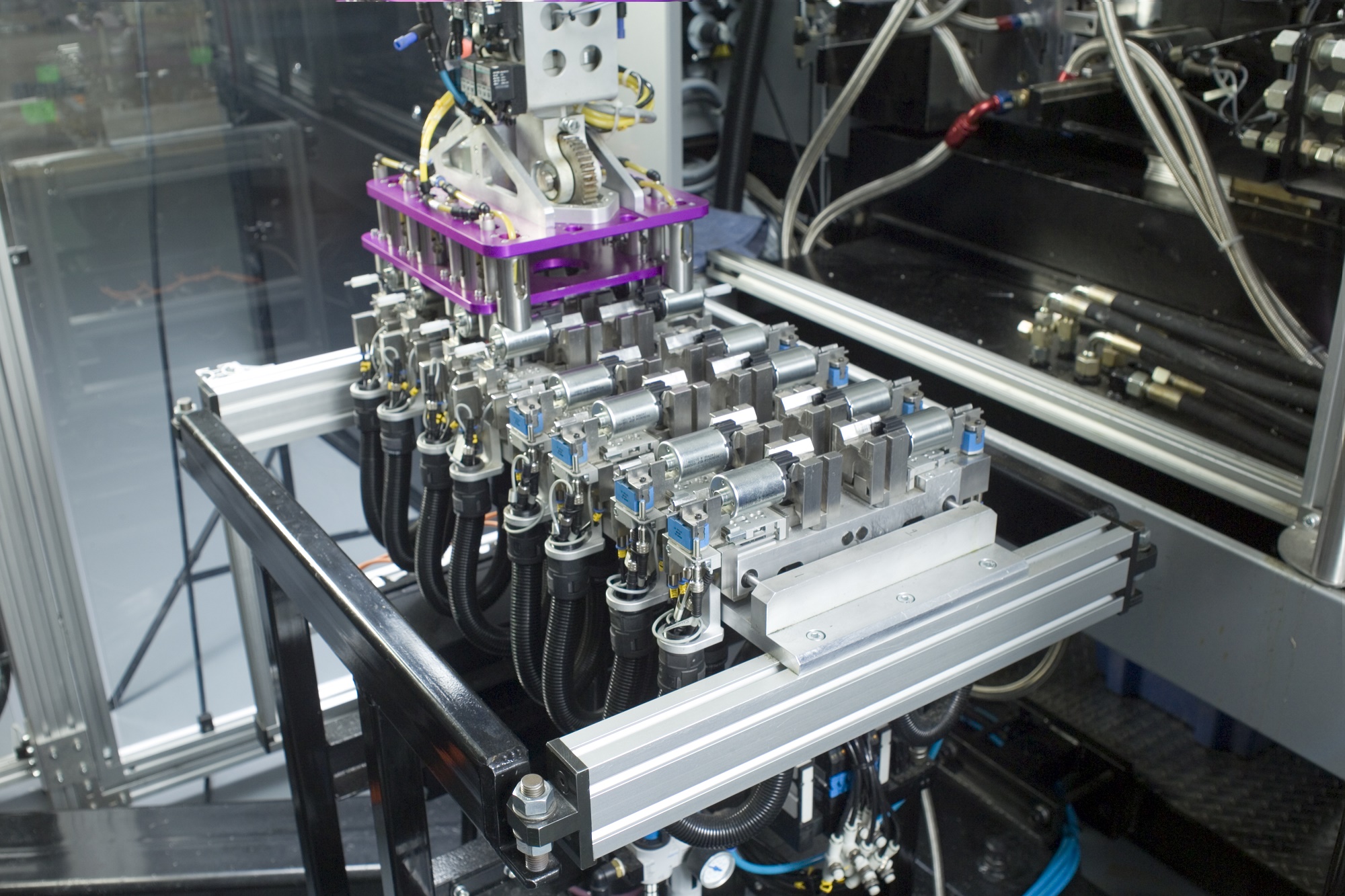

QUALITY ASSURANCE

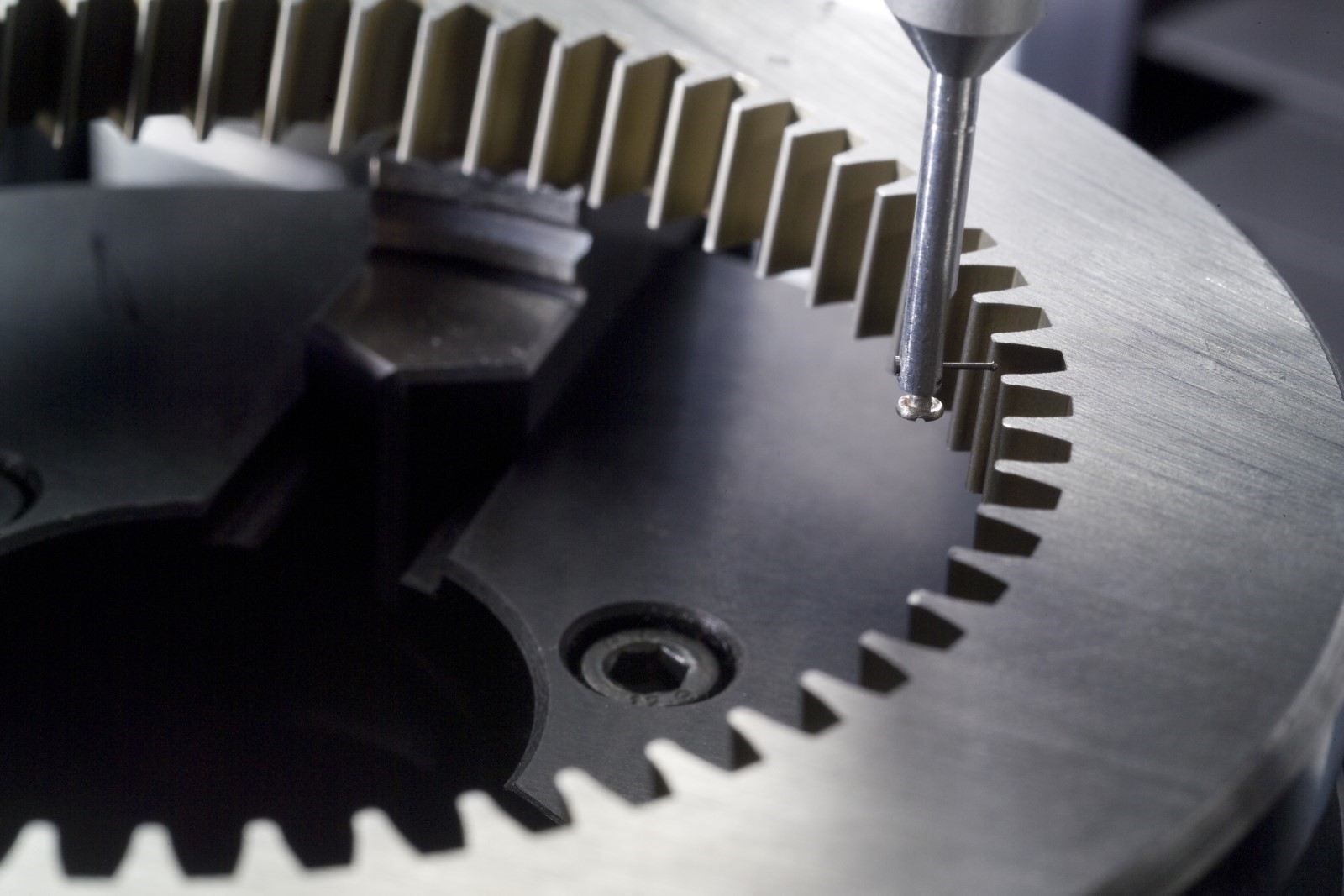

The team at Winzeler Gear has created our quality systems with an emphasis on gear inspection throughout the production process. Our quality lab represents an investment of over $1M of gear inspection equipment to maintain the highest quality product.

GEAR METEROLOGY

At Winzeler Gear, we have high-quality gear metrology equipment to validate and monitor all critical gear characteristics, from the initial prototype all the way to large volume production. Our top-of-the-line systems are here to assure you our gears meet all your dimensional and structural requirements.