Gear Design

Creative Gear Design from Concept to Production

Winzeler Gear is most valuable when engaged in a new program at the design phase of gear product development. The design phases are our only opportunity to create and optimize the gears for economics, engineering requirements, and robust manufacturing from start of production through life of program. We understand it requires a technical team with a wide range of diverse knowledge to provide industry leading designs. Efficient gear product design is a team sport, and it requires collaboration from multiple engineering disciplines.

When we provide gear product design, we are always considering the limits of the plastic material, mold, molding process, and quality requirements. Prototyping is an important step to optimizing gear product design for large volume manufacturing, and our goal is to develop the best possible gear, bringing it from concept to a reality.

Winzeler Gear’s vast experience with a variety of gear design challenges has yielded successful results for our customers in a wide range of industries, primarily in automotive. To learn more about what Winzeler Gear can design for your specific application, contact us today.

Contact Winzeler Gear today to learn more about our gear design capabilities.

Gear Design

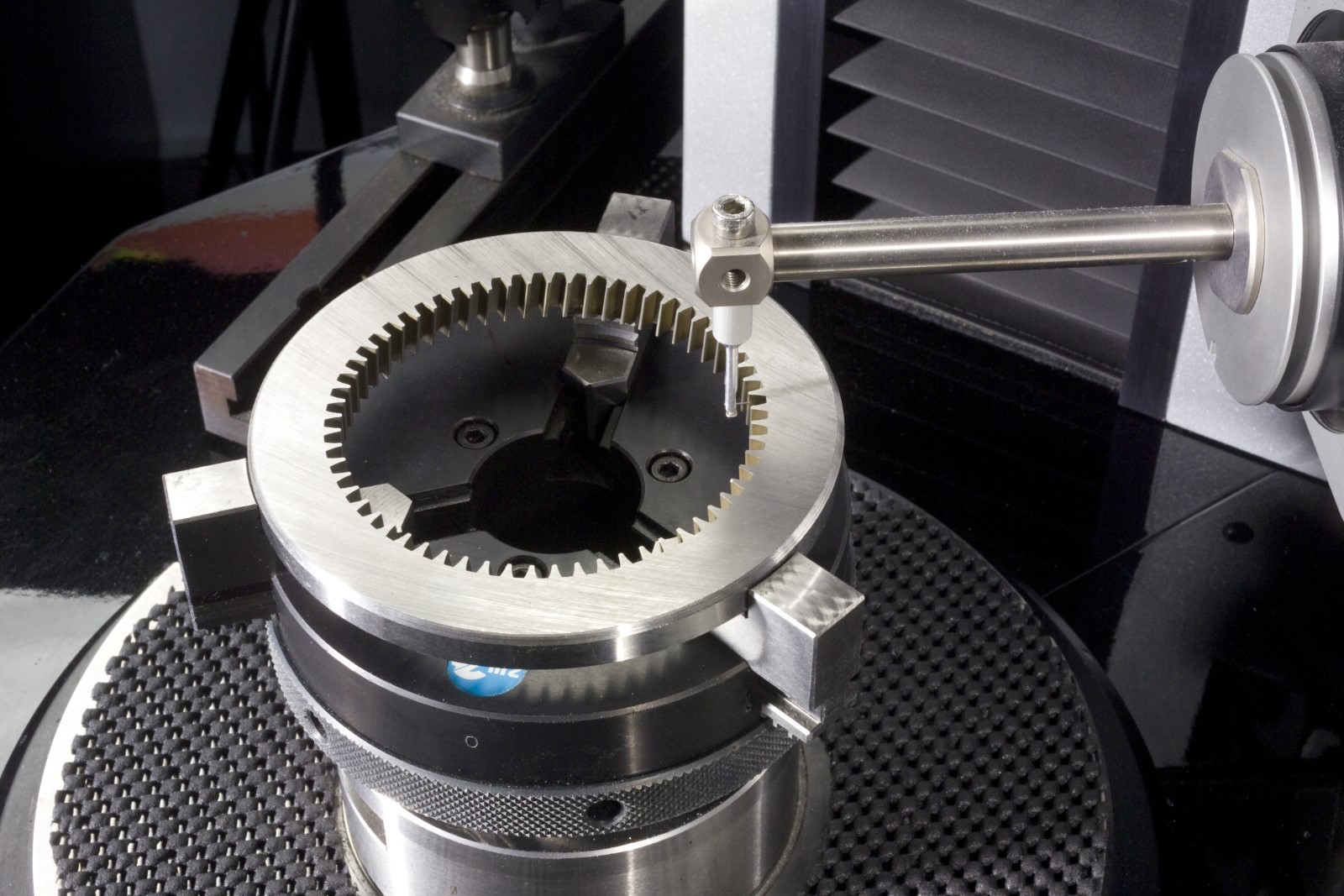

Through gear design prototyping, Winzeler Gear is able to do what we do best: collaborate with partners and customers to focus on optimization and the manufacturability of high-quality gears.

RESEARCH & DEVELOPMENT

Our team has spent years investing in plastic gear R&D to enhance gear design and engineering capabilities. We have designed a wide range of components that operate with the help of our strategic partners, and we continue to work together with them to develop the best gears and assemblies on the market.