Gear Overmolding

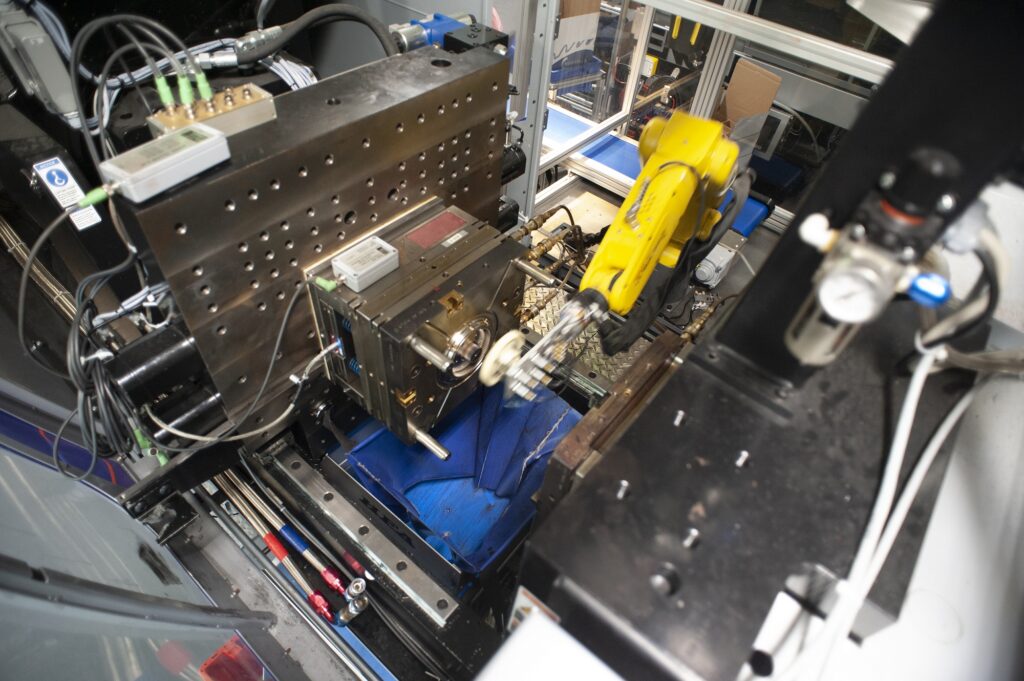

Advanced Plastic Gear Molding Methods

When there are plastic gear requirements that cannot be accomplished with a single material, we can design solutions using metal components or magnets. Gears are more than just the sum of their parts: gears require a variety of advanced molding methods in order to improve gear function and fabrication.

Winzeler Gear is well qualified to collaborate on overmolding gear solutions.

A common application of overmolding for gears is to be molded onto a magnet, resulting in a magnetized sensor gear. Once magnetized, sensor gears can be used to monitor the angular position and/or speed of a gear for a critical application.

At Winzeler Gear, we understand that it requires a technical team of diverse experience and knowledge to provide industry leading overmolded designs. Gear design is a team sport, and we can leverage our strategic partnerships to assist our customers with becoming champions.

Contact Winzeler Gear today for your next gear project requiring overmolding.